Custom Die Cutting Services

Die Cutting Manufacturing

Advantage Converting offers custom, continuous die cutting for fast, economical and environmentally friendly production. Send us your most complex die cut project, and we can provide the highest quality and fastest turnaround in the industry with the most advanced equipment and techniques. If the machine you need doesn’t exist, we can build and implement new equipment for your project.

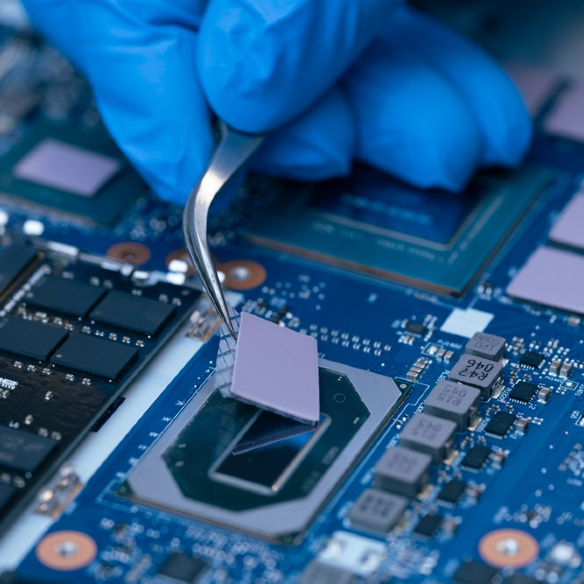

Our experts can create custom dies for any product, including spacers, shims, EMI shields, insulators, conductive parts, thermal products, stickers, labels, masking devices, gaskets, seals, polishing pads, rings, test strips, inserts, reflectors, tear tabs, indicators, washers and markers.

We also offer clean room die cutting capabilities for your most sensitive products, including medical device components, wound care applications and specialty materials. Our state-of-the-art facility features several clean rooms with ISO 7/Class 10,000 and ISO 8/Class 100,000 certifications.

We offer a wide range of advanced die cutting techniques to manufacture these products, customized to meet your volume and application needs

Custom Dies For Die Cutting

At Advantage Converting, our decades of manufacturing experience and innovative equipment lineup enable us to provide the region’s most diverse range of die cutting solutions. Our professionals can evaluate your product needs and expectations to determine the materials and converting processes that will benefit you most. Whether your product requires a single pass or multiple manufacturing phases, we can find a practical, cost-effective solution.

Several examples of our die cutting capabilities include:

- Flatbed die cutting: Flatbed die-cutting typically involves fast-setup platen presses that operate at varied speeds. This process is ideal for prototypes, small and large volume production runs and larger sheet sizes.

- Kiss-cutting: Kiss-cutting cuts only a portion of the material, leaving part of the substrate untouched. This technique is ideal for applications with multi-layered features or products that require part of the original substrate to remain on a liner.

- Roll-to-roll die cutting: Roll-to-roll die-cutting is among our fastest, most efficient converting processes. This method uses rotary die cutters for high-volume runs, often involving several in-line stations to perform multiple cuts, punches or laminations in a single production run.

- Large format die cutting: Advantage Converting has several die presses that can cut simple or complex shapes up to 78 inches wide. These projects often require specialized handling to ensure the highest possible accuracy.

Types of Materials Used For Die Cutting

Advantage Converting works with some of the industry’s top suppliers to offer the most cost-effective, highest-quality raw materials for your die cutting requirements. Our ISO 13485 certification and 3M Preferred Converter status exemplify our dedication to superior quality and service. We can also work with customer-supplied materials for many of our die cutting applications.

Examples of materials we convert include:

Choose Advantage Converting As Your Custom Die Cutter

We’re dedicated to meeting the needs of each client, regardless of project size. We go above and beyond many converters by offering quick turnaround time, unparalleled customer service and cost-effective pricing. We believe in honest, transparent communication, keeping you informed throughout each project phase.

Our team will invest as much time as required until we find the most practical, cost-effective converting solution. We’re agile enough to handle any manufacturing stage, whether you need us to complete the entire project or a single step. In addition, we understand the importance of privacy and prioritize protecting your sensitive product information.

Our strategic location in the Bay Area allows us to serve a broad client range locally, regionally and globally.

See Our Work

Advantage Converting is proud to work with leading companies to solve real-world challenges – from healing wounds faster to protecting scientific equipment orbiting the Earth.

FAQs

Q: What is custom die cutting?

Custom die cutting is the process of shearing materials using specialized tooling (a die) to mass produce a shape. The die has sharp edges that pierce the material, similar to how a cookie cutter is used to make shapes out of dough. Custom die cutting involves creating custom dies to obtain a unique, flat shape.

Advantage Converting uses a variety of advanced die cutting equipment and techniques that allows us to meet various specifications for size, shape, application, and volume needs. We have the capability to die cut up to 78 inches wide, die cut parts in a roll-to-roll process, and can process a wide variety of materials on our existing tooling and equipment.

Q: How can die cutting make production more efficient?

Die cutting is a great option for scaling production and increasing production efficiency. Die cutting can hold very tight tolerances at high output volumes. Tooling can be built to cut multiple parts simultaneously to best yield material, not only increasing efficiency but reducing scrap rate.

Q: What materials can be die cut?

A variety of materials can be die cut. These materials include papers, fabrics, rubbers, foils, foams, non-wovens, films, and plastics.

Advantage Converting can source the materials required for die cutting through our extensive network of partners or use those provided by the customer.