Case Study

Advantage Converting Builds Custom Die Cutting System to Process Challenging Polymer with Precision and Consistency

Challenge

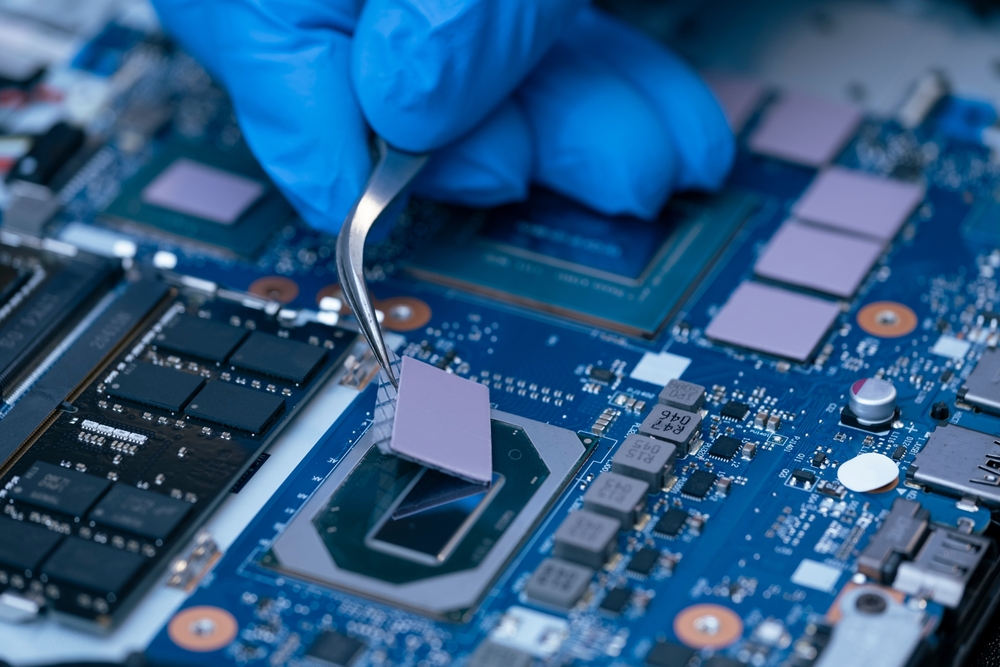

A raw materials manufacturer creates a soft, tacky polymer that is inherently challenging to process. The company produced the polymer in roll form and then processed it further into sheets for die cutting. Because production wasn’t continuous or automated, the company was only able to produce the end product – a thermal pad – at low volume and low scale. With demand growing, the manufacturer needed a partner that could process the material at higher capacity.

Solution

Advantage Converting developed a proprietary process of a roll-to-roll die cutting system that allows the thermal pads to be produced at high volume while maintaining the required precision and consistency. We also developed packaging to keep the thermal pads intact and clean, and prevent them from sticking together during transit and storage.

Results

- Custom process increased the raw material yields by 30% and output tenfold

- Customer grew its business and became a major producer of polymers that are sold globally for thermal management