Green Energy Converting

Renewable Energy Converting Services

At Advantage Converting we believe in the future of alternative energy and are pleased to partner with dynamic energy companies that are pushing the frontier of clean and efficient energy solutions.

Advantage Converting offers the alternative energy industry a range of converting services, including slitting, laminating, and die cutting, as well as component manufacturing expertise. We apply our precision, quality, and attention to detail to help build a variety of projects, from cost and energy-efficient solar panels to batteries that supply clean energy solutions.

Renewable Energy Component Manufacturing Applications

With decades of expertise in materials and manufacturing, Advantage Converting leads the way in producing a comprehensive product range for the renewable energy industry. Our goal is to understand the manufacturing challenges for each client and help develop a practical and efficient solution to meet their production requirements. We manufacture superior-quality components and systems for various applications, including:

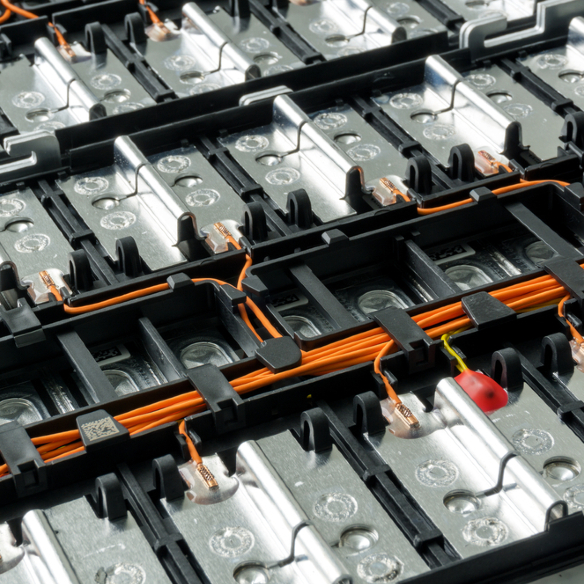

- Batteries: Our advanced processes enable us to produce many different battery solutions, including devices for cellphones, electric vehicles or wearable medical products.

- Bonding and joining: Our bonding and joining capabilities allow us to create products that deliver superior protection against potentially harmful elements like radio frequencies, dust and moisture.

- Electrical insulation: We can slit, die cut or laminate nearly any flexible insulation material — including paper, fabric, film and tape — to create a custom electrical insulation solution.

- EMI/RFI shielding: We convert various electromagnetic interference (EMI) and radio frequency interference (RFI) shield materials like tapes, foils and insulators from some of the most recognized brands, including 3M.

- Gaskets and sealing: We manufacture gaskets and sealing from various materials to increase process efficiency and minimize waste, including foam, tape and rubber.

- Surface protection: We offer surface protection and masking solutions using different lamination and adhesive products for enhanced scratch and scuff resistance.

- Vibration dampening: We convert a broad product range that delivers excellent cushioning, noise-dampening and vibration-dampening properties.

Renewable Energy Manufacturing Services

Renewable energy converting solutions from Advantage Converting allow you to maximize your product offerings by increasing uptime and reliability. Examples of our many manufacturing capabilities include:

- Die cutting: Our custom die cutting processes can meet the most complex converting needs of various materials and applications, from tape and adhesive to mesh and fabric.

- Laminating: We have experience laminating a comprehensive material range, including adhesive backing, multilayered products and dissimilar substrates.

- Slitting and rewinding: Our slitting and rewinding equipment features state-of-the-art technology that converts material at high speeds while ensuring exceptional quality.

- Clean room manufacturing: We offer clean room converting solutions for your most sensitive products, including climate-controlled slitting, rewinding and laminating capabilities.

Materials We Use in Renewable Energy Fabrication

The Advantage Converting team has decades of experience helping clients choose the most effective materials for their renewable energy applications. In addition to being a 3M Preferred Converter, we work with various substrates from some of the world’s top brands to optimize product performance. Several examples of the materials we convert include:

See Our Work

Advantage Converting is proud to work with leading companies to solve real-world challenges – from healing wounds faster to protecting scientific equipment orbiting the Earth.

FAQs

Q: Can Advantage Converting help us develop a brand new solution for the green energy market?

Yes, we love to collaborate with our clients and pride ourselves on solving manufacturing challenges so that our clients can bring innovative solutions to market. Our many years of experience in process development allows us the flexibility to improve designs, evolve specifications, test new materials, and develop new processing methods for proofs of concept, and scale to production volumes.

Q: Given supply chain volatility, how can Advantage Converting help us maintain a stable supply of materials to enable continuous production of our EV and solar products?

With a staff dedicated to managing inventory systems and relationships with raw materials suppliers, Advantage Converting can reliably procure, warehouse, and convert materials for large volume products regardless of disruptions to the supply chain. We ensure continuous production by leveraging our extensive network of raw material suppliers to build up safety stock, and our multiple facilities provide production redundancy.

Q: Can Advantage Converting maintain the surface quality of my material while providing tight tolerance processing?

Advantage Converting understands the importance of maintaining the surface quality and integrity of materials used in the manufacturing of green energy solutions. We can maintain the surface and edge quality of materials while meeting tolerances of ±.004″ for slitting and die cutting, often times even tighter. Or proprietary methods ensure a flat edge, thereby avoiding rippling that is especially common in foils. We also provide clean room manufacturing for materials that require environmental controls.