Slitting and Rewinding Services

Precision Slitting and Rewinding

Advantage Converting offers various slitting and rewinding services for converting operations, including high-speed rewind slitting meeting the tightest tolerance requirements. We can precisely slit a comprehensive range of materials into specific sizes for a wide range of applications with the highest level of quality. We specialize in projects with unique cutting and rewinding requirements, offering clients the most practical and cost-effective converting solutions.

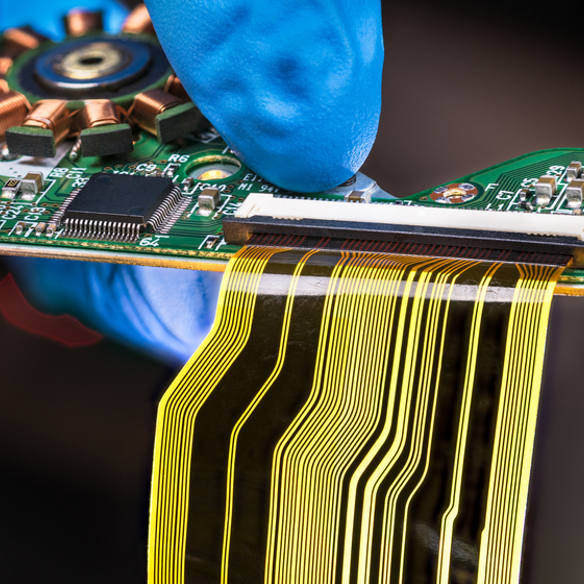

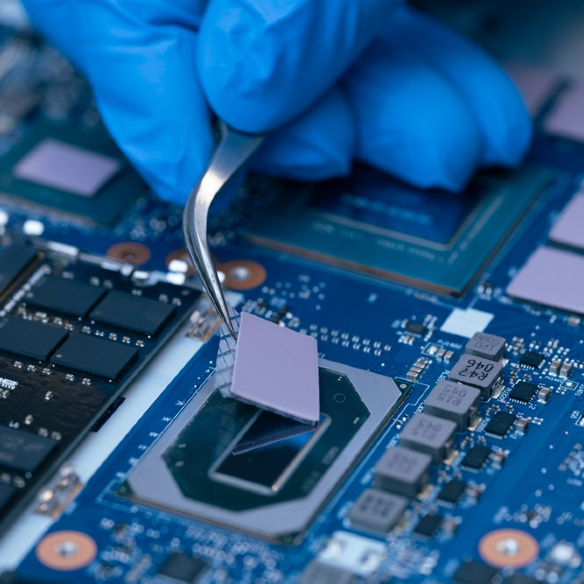

We offer clean room slitting and rewinding capabilities for sensitive materials and products, including medical, electronics and aerospace applications. Our state-of-the-art, clean rooms comply with ISO 8/Class 100,000 and ISO 7/Class 10,000 manufacturing guidelines.

Our Precision Slitting and Rewinding Services

Our team can complete a wide range of precision slitting processes with unwinding and rewinding capabilities based on specific material types and conversion requirements, including edge quality and tolerance. We specialize in different core materials, thicknesses and sizes and can handle your most complex slitting and rewinding conversion needs, including substrates outside our core capabilities.

Depending on the material, we can slit as narrow as 0.5 millimeters and as wide as 76 inches. Typical roll inside diameters we slit are 1, 3 and 6 inches. However, we can do custom jobs with any size cores. Tolerances of ±.004 inches are standard, and tighter tolerances are possible.

Types of Materials We Can Slit

Advantage Converting can slit most customer-supplied materials or supply the necessary material for converting. We partner with top-tier suppliers to offer high-quality, cost-effective raw materials. Our 3M Preferred Converter status and ISO 13485 certification exemplify our commitment to industry innovation and superior-quality products.

Some examples of the materials we can slit or rewind include:

Why Work With Advantage Converting?

The professionals at Advantage Converting are committed to giving each customer the individualized attention they deserve, regardless of the project type or size. We stand above similar converting companies by providing short lead times, competitive pricing and world-class customer service. Our team will keep you informed during each step of your project with clear, transparent communication.

We pride ourselves on taking the time needed to identify the most beneficial converting solution for your production needs, such as our precision slitting service. Whether you want us to handle a specific manufacturing phase or complete your project from start to finish, we can cover all your requirements.

Our strategic location in the Bay Area enables us to serve customers locally and globally. We also respect your company’s privacy and prioritize protecting your most sensitive information.

See Our Work

Advantage Converting is proud to work with leading companies to solve real-world challenges – from healing wounds faster to protecting scientific equipment orbiting the Earth.

FAQs

Q: What is precision slitting?

Precision slitting is the process of cutting a roll of material into specified lengths and widths.

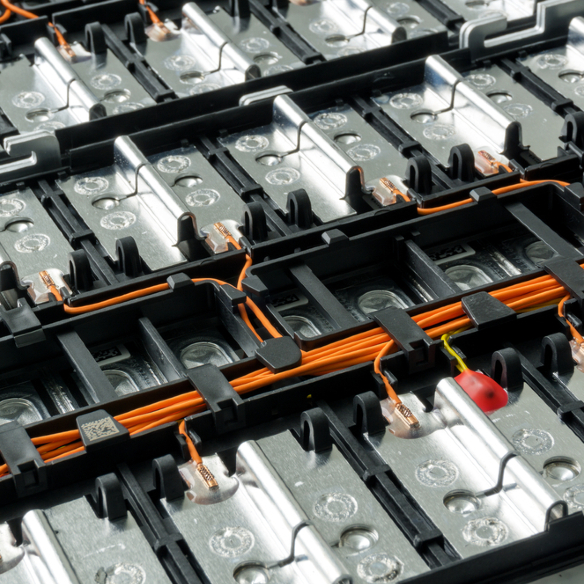

Advantage Converting uses a variety of advanced precision slitting equipment and techniques that allow us to meet a wide range of specifications for size, shape, application, and volume needs. For example, we have precision slit ultra-thin copper (4-10 microns) for advanced lithium batteries as well as large master rolls of proprietary polymers — and everything in between.

Q: What materials can be slit?

A variety of materials can be slit. These materials include papers, films, foils, foams, adhesives, and nonwoven materials.

Advantage Converting leverages years of experience and expertise to evaluate the material and best match the slitting technique and process for the highest quality results.

Q: Can Advantage Converting meet ultra-narrow slitting width requirements?

While slitting specifications are very dependant on the raw material input, Advantage Converting has slit down to .020″ width on single-sided pressure-sensitive adhesives and films.