Clean Room Converting

Clean Room Manufacturing

Clean room manufacturing is crucial in nearly any industry where potential contaminants can adversely affect product quality and performance. Many specialized markets — like medical, electronics and aerospace — benefit from the environmental controls inside clean rooms. At Advantage Converting, we feature several clean rooms with ISO 7/Class 10,000 and ISO 8/Class 100,000 certifications to meet all your sensitive manufacturing requirements.

Clean Room Converting Services

The primary role of our clean rooms is to regulate the number of airborne particles in the production area. We install various filters and other equipment that prevent potential contaminants and harmful particles from entering or generating inside the rooms. Examples of pollutants that can affect some types of converting operations range from aerosol and chemical vapors to dust and airborne microbes.

Clean rooms with ISO certification meet cleanliness levels quantified by the number of measured particles in a specified area. If adhesives, films and other sensitive materials come in contact with pollutants, product appearance, functionality and overall quality can be significantly affected.

Advantage Converting offers clean room manufacturing for every step of the converting process, including:

- Die Cutting: Our advanced equipment, premium-grade materials and years of manufacturing experience result in a comprehensive range of clean room die cutting solutions, from high-volume roll-to-roll die cutting to large-format flatbed die cutting.

- Laminating: We offer a range of clean room laminating solutions for substrates up to 76 inches wide, including pressure-sensitive adhesive and non-adhesive bonding applications.

- Slitting and rewinding: Our clean room slitting and rewinding capabilities include precision slitting of pressure-sensitive and non-pressure-sensitive materials, plus custom reel-winding before shipping.

Why Choose Us as Your Clean Room Converting Company?

Advantage Converting is the ideal choice for a reliable clean room manufacturing with decades of proven manufacturing knowledge. Our experts can work with you to determine the most practical materials and converting processes for your production needs.

Our clean rooms are agile enough to handle any production stage, whether you need us to manufacture your entire order or perform a single phase. We have decades of combined experience partnering with some of the world’s most recognized companies, helping them improve production efficiency and quality while increasing cost savings in a clean room environment.

We believe in honest communication throughout the conversion lifecycle, informing you of your project’s status from beginning to end. Our state-of-the-art facility, strategically located in the Bay Area, enables us to serve clients globally. In addition, we value your company’s privacy and maintain the highest confidentiality.

See Our Work

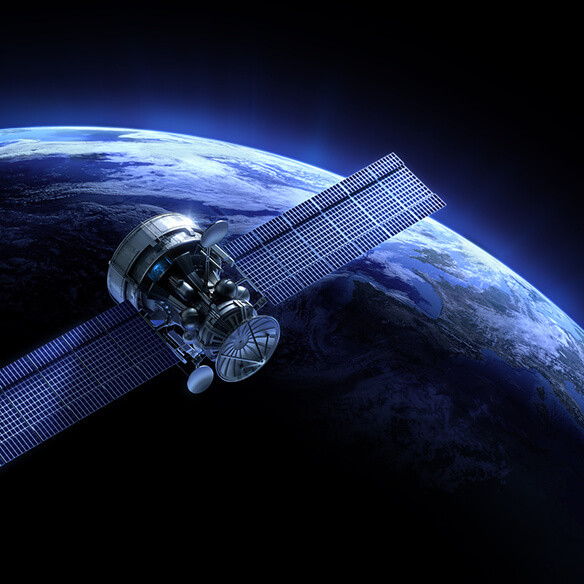

Advantage Converting is proud to work with leading companies to solve real-world challenges – from healing wounds faster to protecting scientific equipment orbiting the Earth.

FAQs

Q: What is clean room manufacturing?

Clean room manufacturing is the use of an enclosed area with strict environmental controls to manufacture sensitive components. The controlled environment – or clean room – limits the presence of dust, airborne microbes, aerosol, and chemical vapors to prevent environmental contamination of sensitive components, such as those for medical, electronic, and aerospace applications.

Advantage Converting has multiple clean rooms that are available for all converted goods. Our clean rooms are certified as ISO 8 / Class 100,000 and ISO 7 / Class 10,000.

Q: What manufacturing processes does Advantage Converting perform in their clean rooms?

We can perform any manufacturing process in our clean rooms, including custom die cutting, laminating, slitting and rewinding, and roll-to-roll manufacturing.

Q: When do I need a clean room?

Clean room manufacturing is primarily used when manufacturing sensitive materials that can be easily contaminated or affected by particles in the air. For example, at Advantage Converting, we have used our clean rooms to manufacture advanced wound care products, solar panel components, and vibration dampeners for the aerospace industry. However, a clean room can be used for any converted good. Our experts can work with you to determine clean room requirements for your project.