Case Study

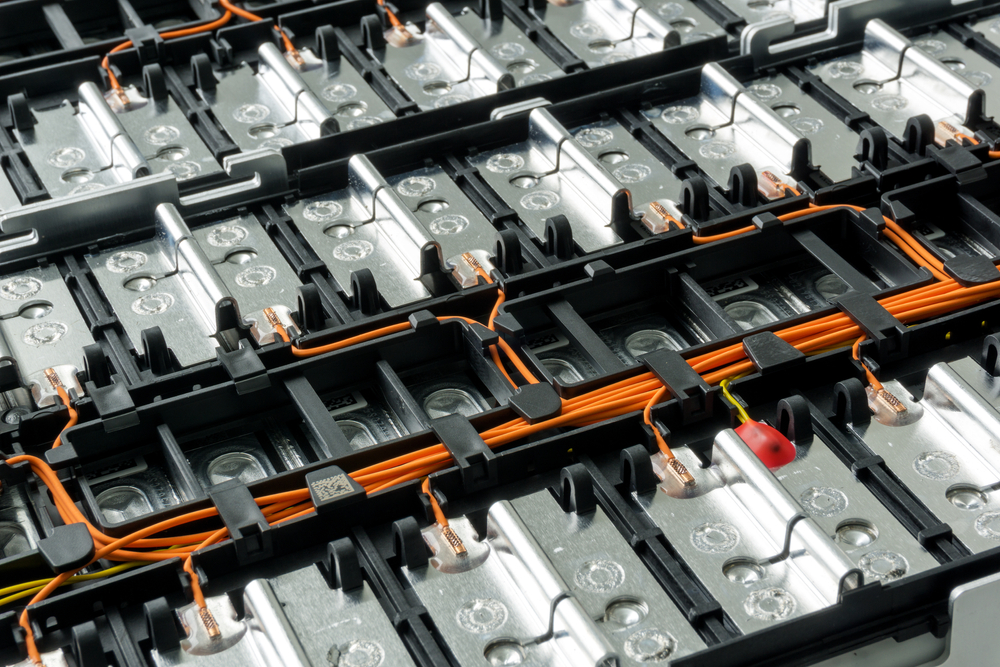

Advantage Converting Solves Common Challenge in Processing Advanced Lithium Batteries, Becomes Trusted Partner of Manufacturers

Challenge

The manufacture of advanced lithium batteries requires precision slitting of ultra-thin (4-10 microns) copper and aluminum foils. Extremely tight width precision and edge quality is critical to downstream applications. Clean room processing is also needed to maintain the surface quality and cleanliness of the material. With the market growing rapidly (at a CAGR of 27%), manufacturers need a converting partner capable of handling these challenging and fragile materials at mass production volumes.

Solution

To meet this demand, Advantage Converting developed proprietary tooling and methodology for slitting ultra-thin copper and aluminum foils at extremely tight tolerances (+/- .002”) with a consistent (smooth) edge quality profile. Quality agreements and clean room processing provide assurance that the materials maintain their integrity. Our ability to meet the requirements for precision and quality at mass production has made Advantage Converting a trusted partner to several advanced lithium battery manufacturers.

Results

- Our ability to meet tight specifications allows customers to increase their yields and productivity

- Consistent high quality input on manufacturers’ automation lines increased output