Electrical Insulation

Electrical Insulation For Applications

Electrical insulators are essential for controlling current flow and protecting sensitive components from electrical interference during operation. These specialized materials require precise converting methods for optimal strength, thermal resistance and dimensional stability. From microscale electronics to complex power systems, properly converted insulation technologies ensure reliable performance and extended operational life.

Advantage Converting combines advanced material science with precision manufacturing to deliver customized electrical insulation solutions. Our ISO-certified facilities and experienced engineering team evaluate your requirements for voltage protection, temperature resistance and mechanical properties to determine the optimal material and conversion process. We maintain rigorous testing protocols throughout each manufacturing phase to ensure your insulation components meet all performance and safety specifications.

Custom Electrical Insulation Solutions

Our engineers create reliable, long-lasting solutions by evaluating various material characteristics, from dielectric strength and surface resistivity to thermal conductivity and moisture absorption. Examples of our capabilities include:

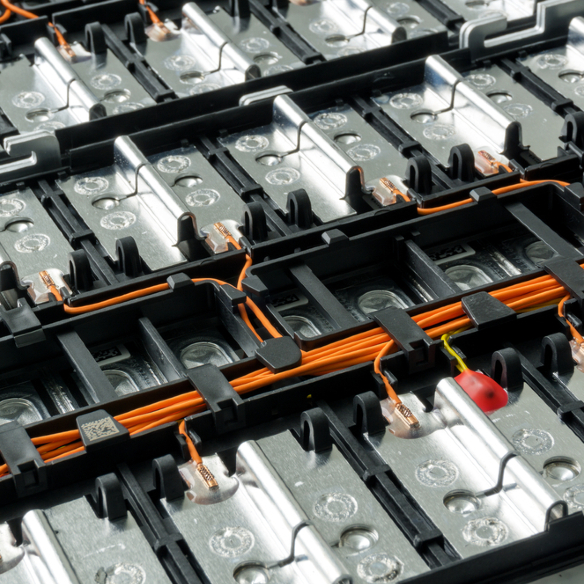

- Multi-layer insulation systems: Our laminating processes bond materials with specialized properties to form a single substrate that increases strength and performance. These solutions provide superior electrical isolation and improve product reliability while saving money through increased manufacturing efficiency.

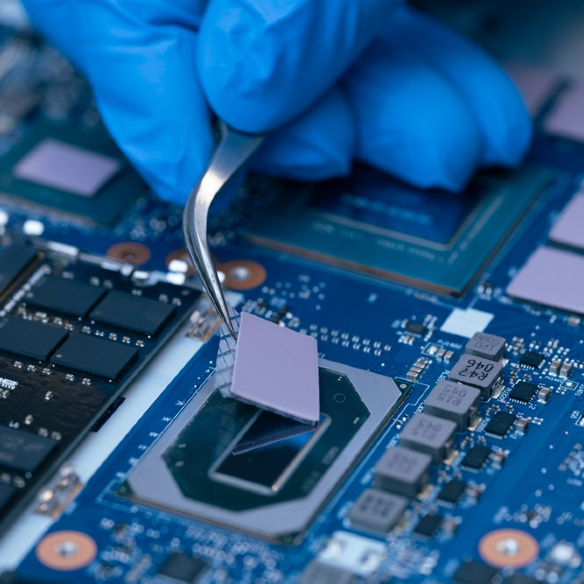

- Precision-cut insulators: We use advanced die-cutting technology to create insulator shapes with consistent edge quality and dimensions. These components ensure proper fit and alignment while maintaining product performance and functionality.

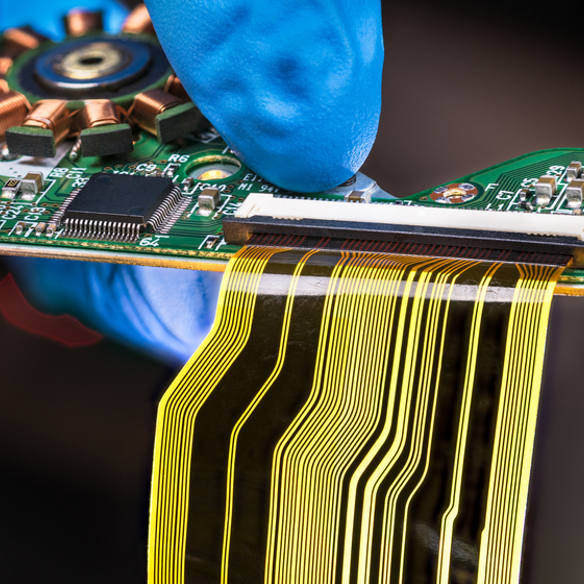

- Flexible barrier systems: Our converted films and composites deliver excellent dielectric properties while staying flexible for dynamic product applications. These materials conform to irregular surfaces or flex during operation without losing their insulative characteristics.

- Atmospheric protection: We convert materials that combine electrical insulation with resistance to moisture, chemicals and temperature extremes. This approach ensures reliable performance in the most challenging operating environments.

Electrical Insulation Die-Cutting and Other Conversion Services

At Advantage Converting, we handle electrical insulation projects of every size, from initial prototypes to high-volume production runs. Each process is set up for optimal handling of insulation materials and undergoes regular testing to verify mechanical properties and performance. Our quality control systems monitor critical parameters throughout production.

Our primary services include:

Laminating

Our advanced lamination machinery creates void-free bonds between insulation layers without compromising dielectric strength. We test bond strength and electrical properties at regular intervals to verify performance.

Slitting and Rewinding

Slitting and rewinding equipment with tension control preserves material flatness and prevents distortion of electrical properties. Continuous monitoring ensures consistent material thickness and width.

Die Cutting

Our flatbed and rotary die-cutters maintain tight tolerances on complex insulator shapes while preserving material properties. Our die-cutting process includes thorough inspections and quality checks to verify critical dimensions.

Clean Room Manufacturing

Our contamination-controlled clean rooms ensure insulation materials maintain electrical integrity. Regular particle counting and environmental monitoring protect sensitive applications.

Electrical Insulation Materials

As a 3M Preferred Converter, we use cutting-edge electrical insulation materials and adhesives engineered for specific voltage, temperature and environmental requirements. Our material selection process evaluates electrical and mechanical properties to ensure optimal performance for your product’s application. We work with leading suppliers to access materials that meet strict quality standards and regulations for electrical safety.

Material types we convert include:

Enhance Your Manufacturing Capabilities With Advantage Converting

Our engineers can develop an electrical insulation solution that meets your specifications and maximizes manufacturing efficiency. Let’s discuss how our expertise in materials and precision converting can improve your product’s electrical performance and reliability. Contact us today to request additional information or to schedule a meeting.